Two types of contact will result in a person receiving an electric shock. Direct contact with live parts involves touching a terminal or line conductor that is actually live. The regulations call this basic protection.

Indirect contact results from contact with an exposed conductive part such as the metal structure of a piece of equipment that has become live as a result of a fault. The regulations call this fault protection.

Basic protection is protection against electric shock under normal conditions.

IEC 60050-195-2021

Basic protection shall consist of one or more provisions that, under normal conditions, prevent contact with hazardous-live-parts.

NOTE. Paints, varnishes, lacquers and similar products alone are generally not considered to provide adequate insulation for protection against electric shock in normal service.

Below are some individual provisions for basic protection:

- Basic insulation;

- Protective barriers or enclosures;

- Obstacles;

- Placing out of arm’s reach;

- Limitation of voltage;

- Limitation of steady-state touch current and energy;

- Potential grading;

- Other provisions for basic protection.

NOTE. In Portugal for low-voltage installations, systems and equipment, basic protection generally corresponds to protection against direct contact.

Fault protection is protection against electric shock under single fault conditions.

EC 60050-195-2021

Fault protection shall consist of one or more provision(s) independent of and additional to those for basic protection.

Below are some individual provisions for fault protection:

NOTE. In Portugal for low-voltage installations, systems and equipment fault protection generally corresponds to protection against indirect contact.

NOTE. Not all of the protective provisions are applicable to both low-voltage and high-voltage.

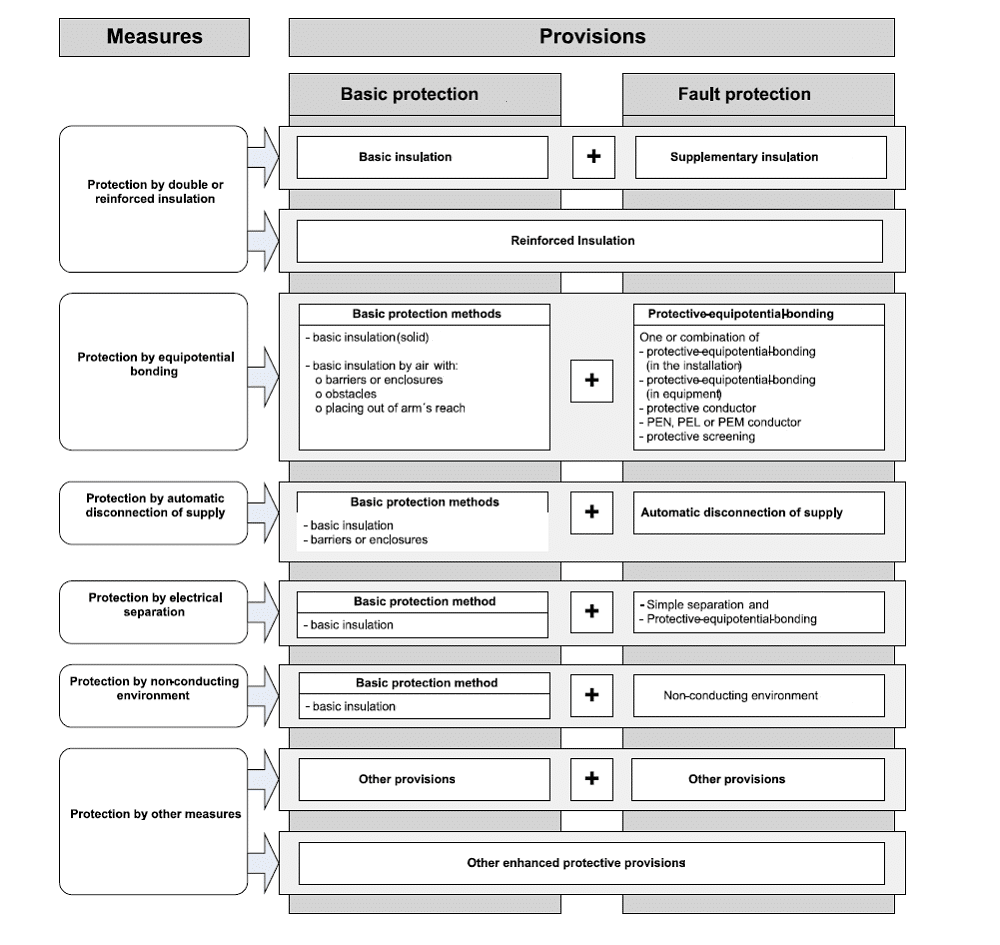

Figure 1 shows the relationship between protective measures and their respective provisions for basic protection and fault protection.

Figure 1 – Protective measures with basic and fault protection

Figure 1 – Protective measures with basic and fault protection