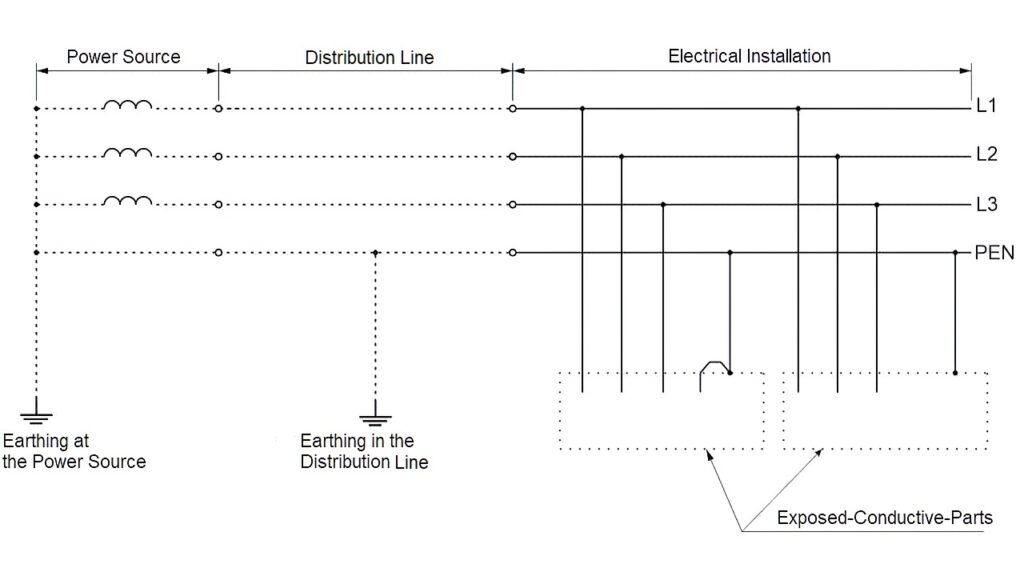

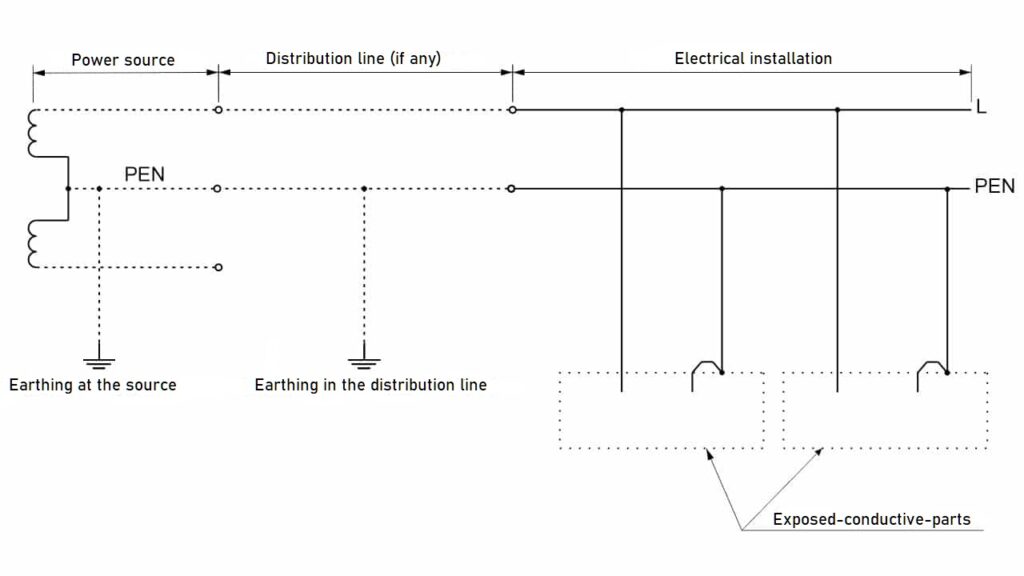

TN-C earthing system (or TN-C system): a distribution system in which one live part of a power source is earthed, exposed-conductive-parts of an electrical installationare connected to the earthed live part of the power source by PEN, PEM or PEL conductors [this term is defined in the IEC 60364-1].

BS7671 provides the following definition: a system in which neutral and protective functions are combined in a single conductor throughout the system.

The Meaning of the Letters T, N, C

The letter codes used for designations of the types of system earthing have the following meanings.

The first letter determines presence or absence of earthing of live parts of the power source:

- T – one live part of the power source is earthed.

Additional earthing PEN, PEM, PEL conductors and protective earthing conductor (PE) in the distribution network (if any) may be provided.

The second letter specifies the earthing of exposed conductive parts of the electrical installation or electrical connection presence between the exposed-conductive-parts and the earthed live part of the power source:

- N – the exposed-conductive-parts have direct connection with the earthed live part of the power source executed by PEN, PEM, PEL conductors or protective earthing conductors (PE).

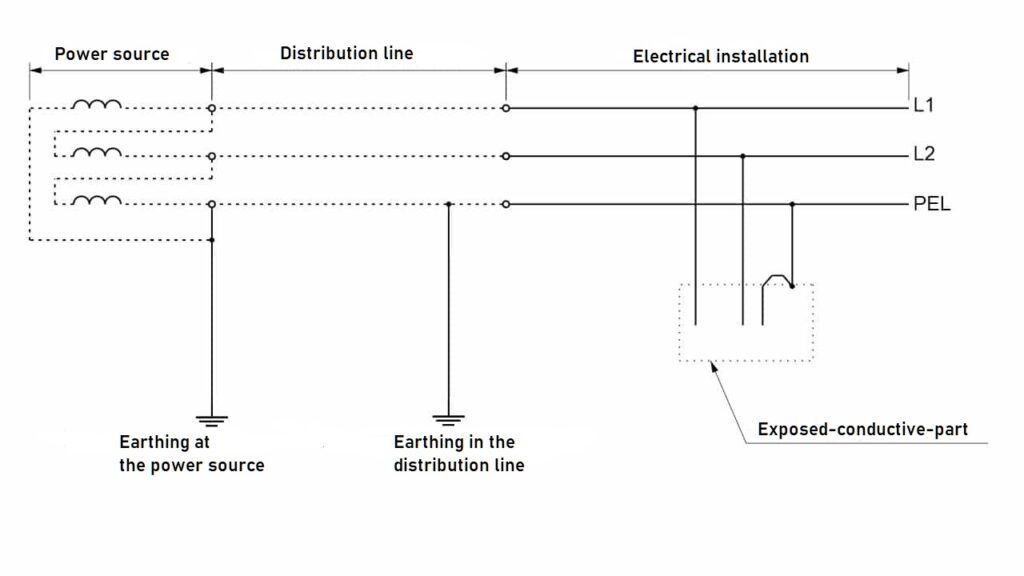

Subsequent after N letters specify how an electrical connection between the earthed live part of the power source and the exposed-conductive-parts of the electrical installation is performed in the distribution system, and also assign features of the arrangement of conductors which carry out the functions of protective earthing conductor (PE) and the neutral (N), mid (M) or earthed line (LE) conductor in the distribution system:

- C – the specified connection is provided throughout the distribution system by means of PEN, PEM or PEL conductors. Functions of the protective earthing conductor and the neutral, mid or earthed line conductor are provided throughout distribution system by means of the single conductor accordingly – PEN, PEM or PEL conductor.

TNC Earthing System Explained

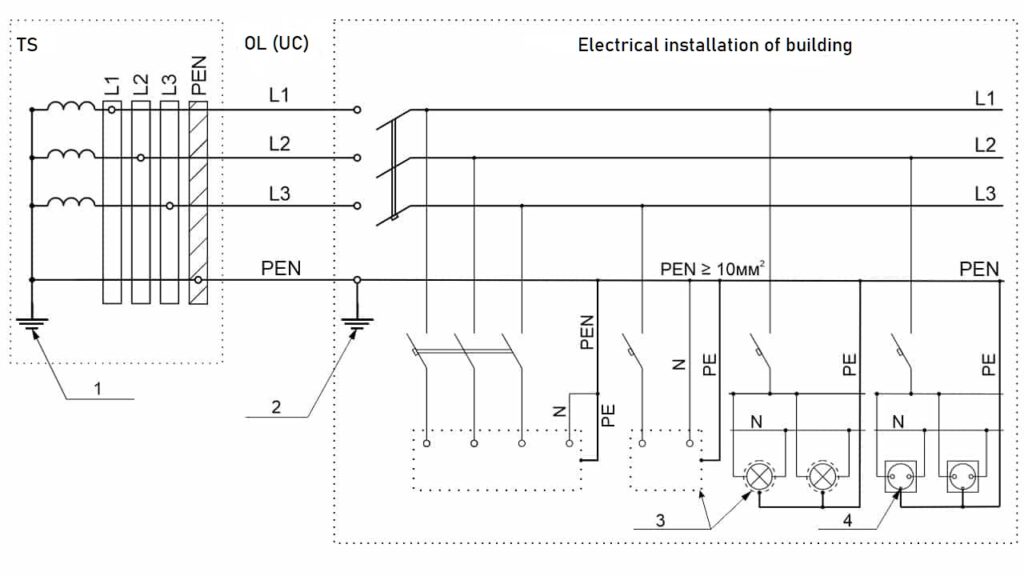

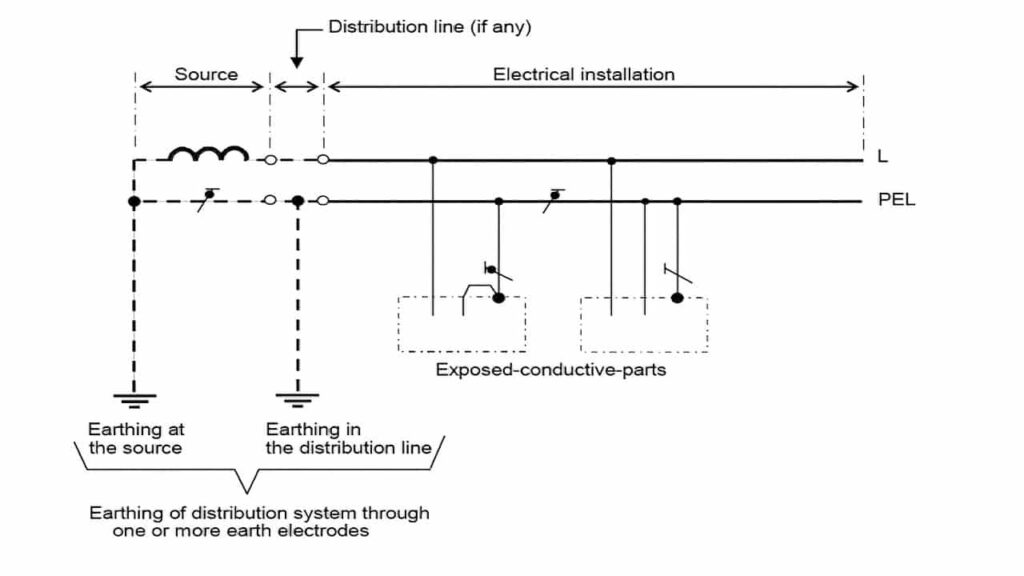

In the TN-C type of system earthing (see Diagram 1), one of the live parts of the power supply is earthed, usually the transformer neutral. All exposed-conductive-parts of class 1 electrical equipment installed in the electrical installation of a building have an electrical connection to the transformer’s earthed neutral. PEN conductors are generally used to provide this connection in both the low-voltage electrical distribution network and in the electrical installation of a building. If the overhead line (OL) is part of the distribution network, its PEN conductor is generally earthed at several points, by performing a so-called re-earthing of the PEN conductor.

The PEN conductor of the electrical distribution network “begins” at the corresponding protective earthing and neutral busbar (PEN busbar) of the transformer substation low-voltage switchgear and “ends” at the input terminal of the switchgear of the electrical installation of a building. The PEN conductors of the electrical installation of a building, to which all exposed-conductive parts of class I electrical equipment are generally connected, begin with this terminal. That is, the PEN conductor, as the protective conductor, penetrates the entire power distribution system from the power supply to the exposed-conductive-parts of the electrical installation of a building.

In some cases, however, the exposed-conductive-parts of class I electrical equipment may be connected not only to PEN conductors but also to the protective earth conductors (PE) of the electrical installation of a building. For example, when three-phase class I electrical equipment is used in the electrical installation of a building, which does not have a neutral and does not require the presence of neutral conductors for its normal operation (see Diagram 2), protective conductors are connected to their exposed-conductive-parts.

If the electrical installation of a building is connected to an overhead line and the branch from the overhead line to the origin is performed with uninsulated wires, the PEN conductor of the electrical distribution network “ends” at the terminal that connects it to the PEN conductor of the incoming cable of the electrical installation of a building.

Examples of TN-C Earthing System Diagrams

Diagrams of the TNC earthing systems are shown below.

- 1 – power supply earthing arrangement

- 2 – the earthing arrangement of the electrical installation of a building

- 3 – exposed-conductive-parts

- 4 – protective contact of the socket-outlet

- TS – transformer substation

- UC – underground cable

- OL – overhead line

With the TNC type of system earthing, the PEN conductor is normally separated into a protective conductor and a neutral conductor at the terminals of the stationary electrical equipment. If class I portable and hand-held electrical equipment is connected by means of socket-outlets, the PEN conductor is separated in the socket-outlet.

When implementing a TN-C system, the cross-section of PEN conductors in the electrical circuits of the electrical installation of a building may not be smaller than 10 mm2 for copper and 16 mm2 for aluminum. The cross-section of phase conductors in the final lighting circuits is usually 1.5 and 2.5 mm2, in the final circuits of socket-outlets 2.5 mm2.

In the electrical installation of a building corresponding to the TN-C type of system earthing, a PEN conductor must be present in all distribution circuits and in the vast majority of the final circuits. Separation of a PEN conductor in such the electrical installation of a building may be performed only when connecting hand-held and portable electrical equipment of class I, performed by means of socket-outlets.

In addition, PEN conductors are substituted for protective conductors in a limited number of final circuits, whose conductors have cross-sections smaller than 10 mm2 for copper and 16 mm2 for aluminum, and in some single-phase final circuits. Such circuits are usually the final circuits of socket-outlets and lighting. In other end circuits, PEN conductors must be used.

The TN-C system can easily be realised when connecting a newly constructed low-voltage installation to an existing or under construction electrical distribution network. However, with this type of system earthing it is difficult to ensure the same level of electrical safety as in the TN-C-S, TN-S and TT systems. In addition, low-voltage installations which correspond to the TN-C type of system earthing are characterized by a higher level of electromagnetic interference, which has a negative influence on sensitive information equipment. For this reason, the TN-C type of system earthing is only permissible in power distribution systems which include low-voltage installations for special applications.

What’s the Difference Between TNC and TNCS?

The TN-C type of system earthing is therefore practically impossible to implement in the most common electricity distribution system consisting of a distribution network and the electrical installation of a building connected to it, because PE protective conductors must be used in the electrical circuits of the vast majority of the electrical installations of buildings. Moreover, it can be argued that, based on their application to the electrical installation of a building, diagram 1 shows an example of the TN-C-S system and not the TN-C system. This does not contradict the requirements of IEC 60364-1 for types of system earthing.

The main criterion on the basis of which the TN-C and TN-C-S types of system earthing are identified is the separation of the PEN conductor for the part of the power distribution system. The international standard establishes the following general rules:

- if only a PEN conductor is used as a protective conductor in a power distribution system, then it is a TN-C system;

- if in a part of an electrical distribution system the PEN conductor is separated into two conductors, a protective conductor and a neutral conductor, then it is a TN-C-S system.

While the standards allow for protective conductors in an electrical distribution system corresponding to a TN-C type system earthing, they do not prescribe any requirements as to the “size” of that part of the electrical installation of a building in which protective conductors are used.

It is therefore sometimes extremely difficult to correctly identify the TN-C or TN-C-S type of system earthing in a particular the electrical installation of a building, if the protective conductors are used in any part of it. To solve this problem, an additional criterion can be applied – the “size” of the part of the electrical installation of a building in which PEN conductors are used.

What Are the Disadvantages of TN-C Earthing?

The “classic” TN-C system can only be realised in those low-voltage installations of special applications which have a small number of class I appliances connected to electrical circuits made with copper conductors of 10 mm2 or more, or with aluminium conductors of 16 mm2 or more. As the proportion of such low-voltage installations is negligible, and such installations in buildings is almost non-existent, the TN-C type of system earthing can be regarded as a “theoretical” type of system earthing, generally used to clarify the 4 “practical” types of system earthing TN-S, TN-C-S, TT and IT.

Ensuring an adequate level of electrical safety in the electrical installations of buildings depends to a large extent on the reliable functioning of protective conductors, namely on ensuring that the continuity of their circuits is guaranteed. The continuity of a protective conductor’s circuit can be maintained for as long as required by the passage of a small current under normal conditions, which does not impair the quality of the connection terminals over time. The PEN conductor has significant operating currents flowing constantly, which can lead to a deterioration of the quality of the connection contacts and even to a loss of electrical continuity in the PEN circuit.

Important! With the TN-C type of system earthing, the same level of electrical safety cannot be ensured in the electrical installations of buildings as with the TN-C-S and TN-S types of system earthing. A higher level of electrical safety in the TN-C-S and TN-S systems is primarily achieved through the use of individual protective conductors in the electrical installations of buildings, through which leakage currents flow under normal conditions. Their values are significantly lower than the load currents that normally flow through PEN conductors.

Minor electrical currents have less negative effect on the electrical contacts in protective conductor circuits. Therefore, the probability of loss of electrical continuity in a protective conductor circuit is significantly lower than in a PEN conductor.

Therefore, protective conductors with a higher degree of reliability than PEN conductors should be used in electrical installations of buildings that are “operated” by ordinary persons. For this reason, it is justified that some countries prohibit the use of the TN-C type of system earthing for residential and public buildings, commercial establishments and medical facilities where PEN conductors are prohibited by national standards in electrical circuits.

Therefore, it is logical to say that low-voltage electrical installations conforming to the TN-C type of system earthing should be operated by instructed and skilled persons who have received special training enabling them to understand the risks and avoid the hazards posed by electricity.

References

- IEC 60364-1

- BS 7671:2018+A2:2022

- Kharechko Y.V. Fundamentals of earthing electrical networks and electrical installations of buildings. 6-th edition, revised and supplementary – Moscow: PTF MIEE, 2012. – 304 с.